Vinyl Liner Conversion

A vinyl liner can form small pin prick holes that allow water to get behind the liner and and stretch the liner. The water can be vacuumed out but may leave wrinkles. Usually once this problems starts it will be ongoing and may even lead to water loss. Converting to fibreglass is one way of never having to deal with this problem again.

Discolouration of the swimming pool vinyl liner is caused from chlorine and UV rays from the sun. The liner will harden with time and may from cracks which are impossible to repair. Restoring your swimming pool with a fibreglass membrane will eliminate this problem.

Coping coming away from the wall and taking the liner with it is a common problem in older vinyl liner pools. This can lead to water loss and stretching of the vinyl liner. Once this occurs it is difficult to repair as the coping will usually need to be re-attached to the wall prior to the liner being reinstalled. This is not possible with 10 year old swimming pool vinyl. Fibreglass pool membranes never have this issue.

A tear in you vinyl liner will usually lead to water loss as the pool is constructed of brick and rendered. The shell is not in any way waterproof so any water that gets behind the liner will leech into the ground. Replacing your vinyl liner with a fibreglass swimming pool membrane will waterproof the shell of the swimming pool.

Due to a skimmer box being submerged, the beading that seals the skimmer box to the liner can fail leading to water getting behind the liner. Sealing the skimmer box to the fibreglass membrane during the pool renovation will prevent this from ever happening to your newly restored swimming pool.

Water loss can occur for numerous reasons in a vinyl liner swimming pool. Fibreglass is the most comprehensive solution for waterproofing any swimming pool and will remain waterproof for more than 20 years.

Fibreglass Vs Vinyl Pool Liner

When it comes to pool liners, fiberglass and vinyl are two popular options. While both have their advantages, fiberglass pool linings offer several unique benefits that make them a better choice for homeowners. In this article, we’ll take a closer look at the advantages of fiberglass pool linings versus vinyl pool liners.

Durability is one of the biggest advantages of fiberglass pool linings. Unlike vinyl, which can crack, peel, or fade over time, fiberglass is a strong and durable material that can withstand the harsh conditions of a swimming pool environment. This means that a fiberglass pool liner will last longer, requiring less maintenance and saving you money in the long run.

Another advantage of fiberglass pool linings is that they require less maintenance. The smooth, non-porous surface of a fiberglass pool makes it more hygienic and easier to clean, helping prevent the growth of bacteria, algae, and other contaminants. This keeps the water clean and safe for swimming, making fiberglass pools a great option for families with young children or for those who are concerned about pool hygiene.

Customization is another major advantage of fiberglass pool linings. They are available in a variety of shapes, sizes, and colors, so you can choose the perfect pool for your home. Whether you want a traditional rectangular pool, a free-form pool with curves, or a unique shape that fits your backyard perfectly, fiberglass pool linings can be customized to fit your specific needs and preferences.

Installation is also quicker and easier with fiberglass pool linings. They can be installed in just a few days, meaning you can start enjoying your new pool sooner without the need for a long, drawn-out construction process. Quick installation also means less disruption to your daily life, as the process is typically fast and easy.

In comparison, vinyl pool liners are not as durable as fiberglass. Over time, vinyl can crack, fade, or become brittle, requiring frequent repairs and replacements. Additionally, vinyl pool liners are not as customizable as fiberglass. They are typically only available in a limited range of colors and patterns, making it difficult to find a liner that perfectly matches your pool and your personal style.

Finally, fiberglass pool linings are a more energy-efficient option. They are better insulated than vinyl, which means they retain heat better, keeping your pool warm even on cool days. This, in turn, can help reduce energy costs, saving you money on your utility bills in the long run.

In conclusion, fiberglass pool linings offer several unique benefits that make them a better choice than vinyl pool liners. With their durability, low-maintenance, customization options, quick installation, and energy efficiency, fiberglass pool linings are the ideal choice for homeowners looking for a high-quality, long-lasting, and attractive pool solution. Whether you’re looking to add value to your home, create a backyard oasis, or simply have a place to cool off on hot summer days, fiberglass pool linings are the perfect choice.

118

Vinyl Pools Converted

5 Year Guarantee

Against cracking, Peeling or Blackspot

The Process

Renovating a vinyl liner swimming pool using a fibreglass membrane is the best way to eliminate any of the old problems faced with having a vinyl liner swimming pool. Vinyl is an old technology that is prone to problems and usually requires constant maintenance. Rejuvenating your backyard by replacing you problematic vinyl liner with a high grade fibreglass membrane is the best way to create a carefree swimming pool. The process of the vinyl liner renovation is listed below

- Empty the swimming pool water.

- Tarp pool to protect from sunlight and help prevent debris going into the pool.

- Remove the vinyl liner and coping strip from the swimming pool..

- Installation of any re-modelling inclusions, such as ledges, steps or plumbing items.

- Prepare and repair the surface of the swimming pool and prime if needed.

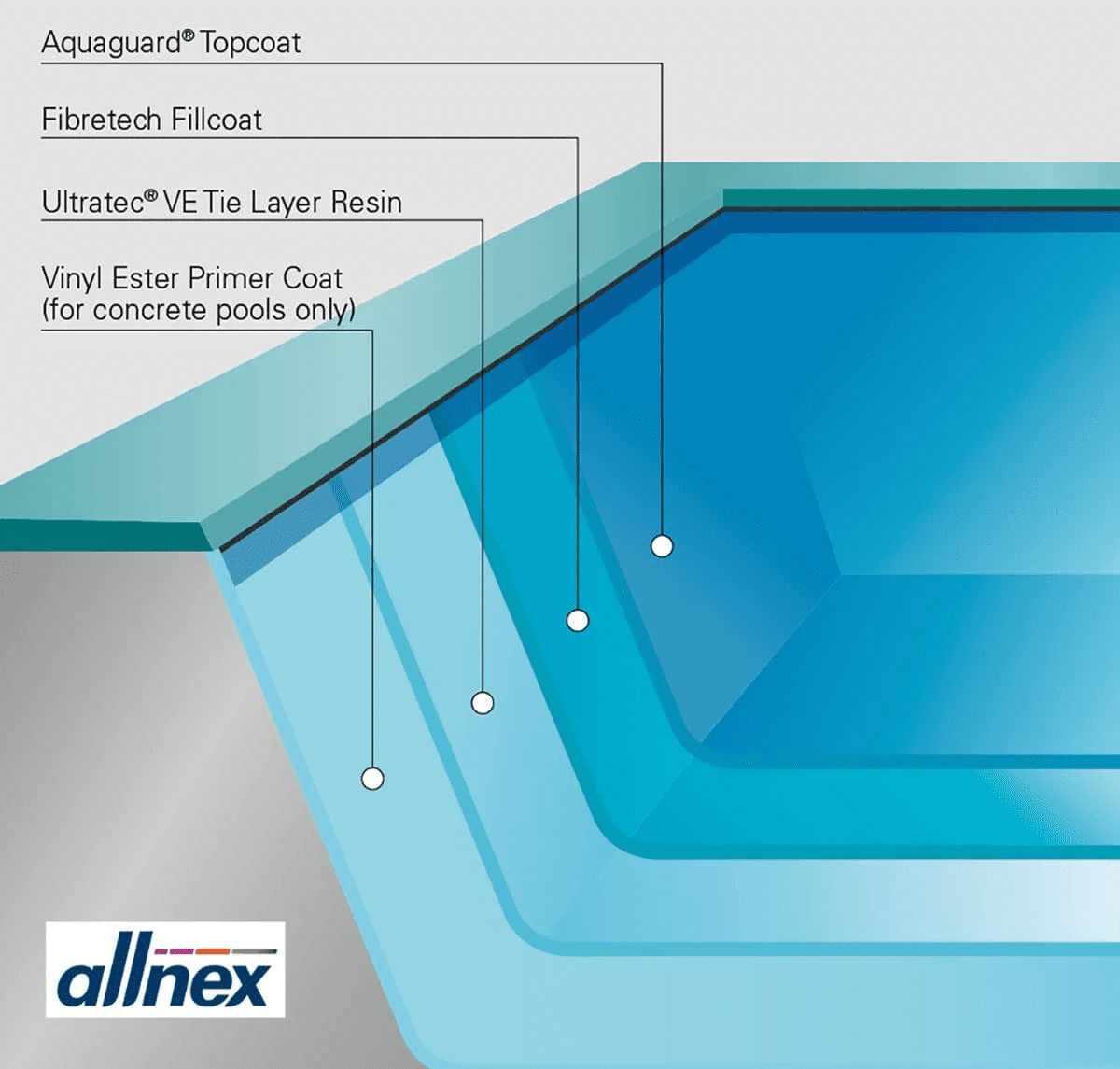

- Fibreglass entire pool surface in conjunction with a high grade vinyl ester resin.

- Application of vinyl ester Fill Coat, to fill fibreglass strand pattern & pre-colour the new surface ready for the top coat.

- Application of Top coating, manufactured to specified choice of colour using the latest UV stabilising technologies, to give a superior & durable finish.

- Clean up and remove tarp.

- Handover.